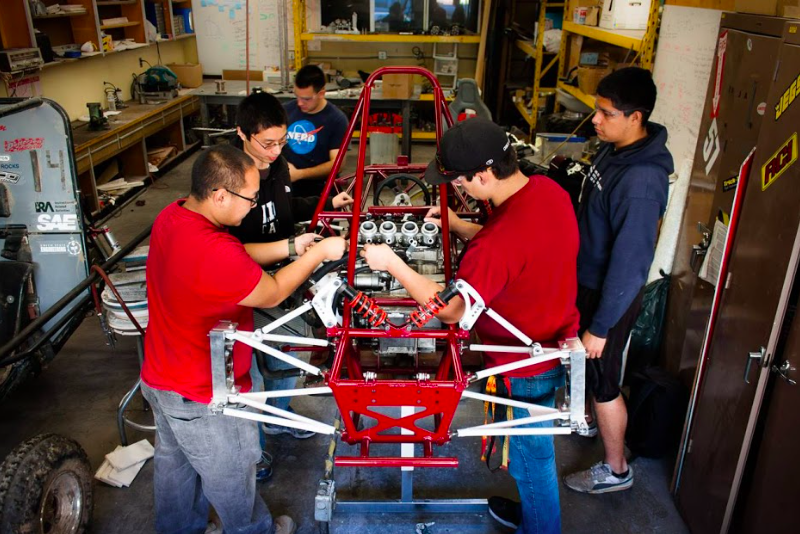

Just follow the piercing sound of metalwork, welding and heavy-duty machines and you’ll find yourself in the courtyard of Plumas Hall, where the Society Of Engineers at Chico State are hard at work designing a race car from scratch for the Formula Society of Engineers competition.

The student design competition is organized by SAE International. Teams from all over the world come to compete, and Chico State will be submitting a new and improved automobile for the event. This year’s tournament will be held in Lincoln, Nebraska on June 17–20.

Chico State’s Society of Engineers team has built one car in the past.

However, its new and improved car this year will top previous designs, said Tyler Gellinck, junior mechanical engineering major and team member.

“We learned a lot from the old one, like what areas needed improvement and redesign, so we used that as a foundation,” Gellinck said. “The experience from building that one taught us a lot about what we need and what we need to incorporate for the next car.”

When it comes to building a car though, it’s not all fun and games. There’s a strict process that the team must follow in order to have the car finished on time and working properly.

Currently the team is in the design stage, where they design all of the components of the car and determine exactly what they need to build it. Then they enter the manufacturing stage, where they start to build and put the car together.

Sam Rabellino, junior mechatronic engineering major and president of the team, said there are dangers associated with the process.

“We work with a lot of dangerous machines,” Rabellino said. “The CNC machines in Langdon are really cool, but they spin at 600 RPM’s. So if you don’t program it right, it can take a tool and just shove it straight into the material which will break the tool and send pieces flying out.”

Wearing protective equipment, such as safety glasses and fireproof bodysuits, is essential when working in the manufacturing zone.

The team plans to have a model ready and built by the end of winter break, which they will then start testing. They use a private road located in Chico to drive the car, but space limitation causes many dangers for the drivers when attempting to get up to a speed of about 60 miles per hour.

“We couldn’t do the full length because we didn’t have enough space,” Rabellino said. “So by the time you get up to speed, you pretty much have to slam on the breaks because you’re going to hit a fence or something.”

Along with dangers in relation to the process, the project requires a lot of money that comes out of the pockets of the team members.

Vincent Uribe, sophomore mechanical engineering major and public relations leader for the team, said about $8,000 goes into the car just from personal cost. That doesn’t include the $9,150 the team needs in order to its design into the race.

To help with these expenses, the team held a fundraiser Dec. 3 at Woodstock’s Pizza to help with preparations for the car, enrollment into the competition and the excursion to Lincoln, Nebraska.

Despite these risks, physical labor and high expenses, the dedicated team members still reflect on the wonderful experience and excitement they get from working on this project.

“We have specific meetings throughout the week, and then there are certain sections of the car that meet up and do work,” Gellinck said. “But I would say it’s kind of like a part-time job. At least 20 hours a week, minimum. Once you get to drive the car and see what all of your work has accomplished though, it’s pretty cool.”

To learn more about Chico State’s Society of Engineers team and keep up with the progress of its journey, visit its Facebook page. The page includes information on sponsors, team members, events and how to get involved.

“I do this because it teaches us a lot about teamwork, and not only that, but for engineering,” said Uribe. “We learn a lot doing this rather than just in the classroom sitting down. Then we can apply it toward that also.”

Stephanie Schmieding can be reached at [email protected] or @stephbottt on Twitter.